Request a No-Obligation Quote For Steel Surface Preparation, Linings and Coatings

Request Pricing InformationCase Study: SÄKAPHEN Lining of Pipework

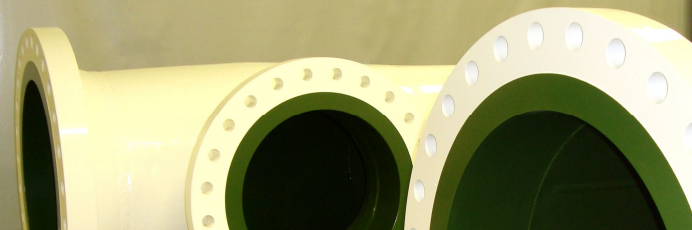

SÄKAPHEN Si14E Lining of Meter Prover Spools

Client

Meter Prover Manufacturer

Scope of Work

Internal Lining of Meter Prover Pipework

Products

SÄKAPHEN Si14E

Substrate

Carbon Steel

Coating System

The Meter Prover Spools were grit blasted internally to a cleanliness standard of Sa3 in accordance with ISO 8501-1:2007 with an average surface profile of 40 to 60 microns. The lining is applied from solution in a series of thin layers, with an air dry period between coats and a low temperature stoving to assist solvent release and part polymerise the resin. Conventionally, 25-40 microns are applied at each coating application.

When the lining has attained the specified thickness and continuity, the final cure is completed by placing the component in the stoving oven and raising the temperature to 200°C. The exact duration and the rate of temperature rise will depend on the mass and wall thickness of the construction. The lining is tested for thickness, continuity and cure when cool.

Coating Details

One of the SÄKAPHEN range of thermal hardening SÄKAPHEN Resins, SÄKAPHEN Si14E is an unfilled Phenol Formaldehyde resin lining applied to pipework, heat exchangers, condensers, storage tanks, meter provers, pumps, turbines, fans and other metal fabrications operating at temperatures up to 180°C in certain cases.

Photographs

Main Image: SÄKAPHEN Si14E Lined Prover Spools

KUE Group Limited, Birksland Street, Bradford BD3 9SU United Kingdom Tel: +44 (0)1274 721188www.kuegroup.com